FAQ

| The CLEAN PVC UNION BALL VALVE I bought is not compatible with another one I have. | |

|

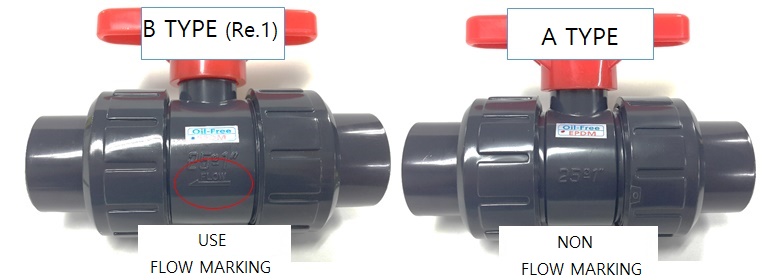

┼ The CLEAN PVC UNION BALL Valve and the UNION SOCKET come in “A-TYPE” (the old model) and “B-TYPE” (the new model). These two types are not compatible with each other. ┼ On the other hand, the SOCKET TYPE from 65A to 100A is compatible with one another. To Distinguish from A-TYPE to B-TYPE: One is stamped with FLOW, and the other is not.  |

|

| How shall a STRAINER be installed and cleaned? | |

|

┼ Our T-STRAINER should be installed in such a way that the FILTER cleaning area is located at the bottom for easy maintenance. ┼ For strainers from 15A to 50A, the BONNET and the FILTER are integrated into one. Remove the BONNET to clean and remove sludge. ┼ For strainers from 65A to 300A, remove the BONNET, and insert a long thin rod into the BODY to scrape any foreign substances that are stuck in the FILTER.  * For safety reasons, it is recommended to stop operating the piping and remove the fluid before cleaning. |

|

| What type of rubber is used in the product? | |

|

┼ For EPDM O-RING / SEAT / DIAPHRAGM, they are indicated with a blue cap on the handle. ┼ For FPM O-RING / SEAT / EPDM+PTFE DIAPHRAGM, they are indicated with a white cap on the handle.  * The above indications apply to generic products and may vary for special products. |

|

| The handle of the BALL VALVE turns, but the ball does not. | |

|

┼ If the valve handle is operated with excessive force while the ball is stuck, it may be difficult to operate

normally due to deformation of the handle and the ball.

┼ If there was no problem with the initial operation of the handle, it could be inferred that the ball has been deformed by the fluid as excessive torque is gradually required. In such cases,

we recommend changing the material or type of the valve. |

|

| The backflow prevention function of the CHECK VALVE is not working correctly. | |

|

┼ Because the disc of a BALL CHECK Valve operates with gravity, it can operater normally only in vertical pipes. ┼ The CHECK VALVE should be installed with attention to the direction of the fluid. If installed in the wrong direction, it does not work correctly.

┼ When using strong chemicals that are not suitable to the valve material, the valve material may deform causing the disc to be trapped. In such cases, we recommend changing the valve material.

┼ The SWING CHECK VALVE can be applied to the vertical/horizontal piping as it operates in relation to its axis, but it may be difficult to operate normally if the piping is tilted or twisted.

┼ Chemicals may corrode the SEAT (rubber) causing a leak. In such cases, we recommend changing the SEAT material. |

|

| The handle on the ball valve is stuck. | |

|

┼ The symptom may be caused by a

sludge stuck in the ball valve.

┼ It is best to improve the fluid environment. If it is difficult to improve the environment, consider adding a strainer, or replacing the valve with a diaphragm valve with high resistance to sludge. Temporary

Troubleshooting 1. Remove

the handle as shown in the following photo. 2. Connect the stem using the

monkey spanner as shown in the following photo. 3. Repeat the opening and closing

(90˚) of the handle to release the stuck ball. 4. Re-assemble in reverse order.

※ Please be aware that it may strain the VALVE itself as it is only a

temporary solution. |

|

USA

USA

MMR

MMR CHN

CHN TWN

TWN FRA

FRA IDN

IDN JPN

JPN KHM

KHM KOR

KOR MYS

MYS PRT

PRT ESP

ESP THA

THA VNM

VNM